Introduction

India’s manufacturing industry has been experiencing rapid growth in recent years, thanks to a thriving economy and a strong focus on technological innovation. At the forefront of this exciting revolution are Advanced Manufacturing Technologies such as Robotics, Automation, and 3D Printing. These cutting-edge technologies have given Indian manufacturers a competitive edge, allowing them to boost productivity, quality, and reduce costs.

Advanced Manufacturing Technology involves the use of modern technologies to manufacture products and services, which results in lower production costs and increased manufacturing efficiency. India is continuously advancing with new technologies and machinery, making advanced manufacturing with technology more accessible and reliable.

Here are some of the most popular Advanced Manufacturing Technologies in India

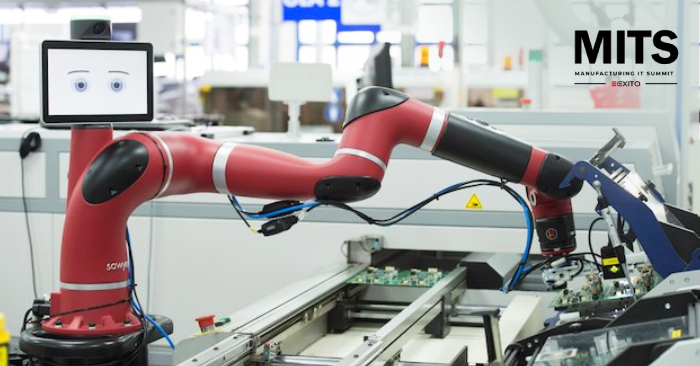

1. Robotics

The adoption of robotics in India’s manufacturing industry is still in its early stages, but it has shown immense potential to transform the industry. According to a report by the International Federation of Robotics, India is projected to see a growth rate of around 20% per year in the need for robotics adoption in the coming years.

Robotics can significantly enhance productivity, quality, and safety in the manufacturing industry. It can also reduce the dependence on manual labor, resulting in cost savings for manufacturers. Already, robotics is being used in India’s automotive industry, where it has enabled manufacturers to improve production efficiency and reduce defects.

2. Automation

Automation refers to the use of technological equipment or software services to automate any task that used to be done by humans before. It is a broad term that includes robotics, machine learning, and artificial intelligence. Automation has been widely adopted in India’s manufacturing industry, particularly in the automotive and electronics sectors.

Automation offers numerous benefits, including increased productivity, improved quality, lower costs, and improved safety. Automation has also enabled manufacturers to produce high-quality products at a faster rate, leading to improved competitiveness in the global market. In India, the adoption of automation is driven by the need to improve efficiency and reduce costs in a highly competitive market.

3. 3D Printing

3D printing is the process of printing a three-dimensional object referring to a digital blueprint or prototype. 3D printing is currently trending among the vast majority of industries and sectors, including manufacturing, construction, aerospace projects, and even in the restaurant business. Although 3D printing is still in its early stages of adoption in India’s manufacturing industry, it has the potential to revolutionize the industry.

The benefits of 3D printing in manufacturing are numerous. It can significantly reduce lead times, enable customization, and reduce waste. 3D printing can also enable manufacturers to produce complex parts that would be difficult or impossible to produce using traditional manufacturing methods. In India, 3D printing is being used in the aerospace, automotive, and medical industries, among others.

Conclusion

Advanced Manufacturing Technologies such as Robotics, Automation, and 3D Printing are transforming India’s manufacturing industry. These technologies offer significant potential to improve productivity, quality, and safety while reducing costs and enhancing competitiveness. As India continues to grow its manufacturing industry, the adoption of these technologies will play a crucial role in ensuring its success. The Indian government has recognized the importance of these technologies and has taken steps to promote their adoption.