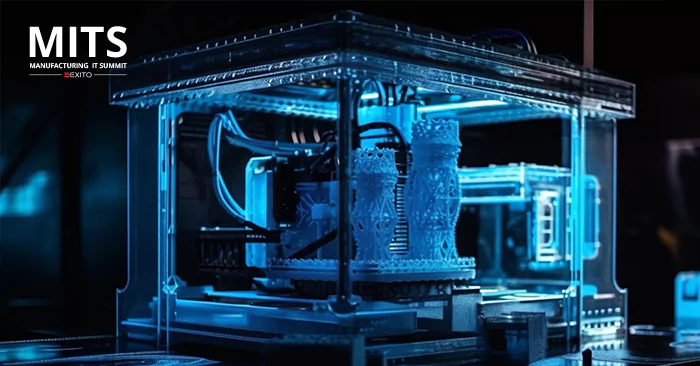

After Industry 4.0 made its appearance in our economy, industries across various sectors haven’t been able to resist the urge to use latest technological trends, the sole reason being, sustainability and rapid generation of outcomes. As per Fortune Business insights, the 3D printing market size was estimated to be at 15.10 billion dollars in the year 2021. This clearly states that, Additive manufacturing is one such industry 4.0 invention that’s at the forefront and serves as a pillar of support to industries across the world.

As more and more industries adopt Additive manufacturing technologies, they’ve come to realize the benefits that these technologies bring along. That being said, some of the most popularly used 3D printing materials include, ABS, Nylon, resin, Polylactic acid, Titanium, High Impact Polystyrene, etc.

3D printing technology and Additive manufacturing processes have become widely popular due to their ability to produce faster and with greater efficiency, while also reducing unnecessary waste production.

In this blog, we will explore the ways and means in which Additive process manufacturing is reshaping numerous industries:

- Promotion of sustainable practice:

Industrial organizations are all evolving towards a better and greener tomorrow by utilizing addictive manufacturing techniques in their processes. Moving forward, companies are going to prioritize sustainability more than ever by reducing energy consumption and practicing optimum utilization of resources.

One of the best examples of sustainability linked to additive manufacturing process includes, Adidas introduced a type of sneakers which utilizes 3D printing to create a brand new pair once it gets worn out. The entire shoe can be destroyed and its materials can in turn be used to make brand new pairs, mitigating waste and promoting a much-needed recycling chain.

- Enabling design innovation through automation:

Combining generative design with 3D printing can help make design iterations which could not otherwise be done by a traditional approach. This kind of combination allows the construction of elaborate and intricate designs.

One notable example includes the design of aerospace parts. Airbus is one such company that adopted the combination of both additive manufacturing and automated design to produce innovative parts of aircraft. This kind of integration has enabled engineers to set goals clearly as per their requirements. This gives them an array of options to choose between before proceeding with the next step of creating them.

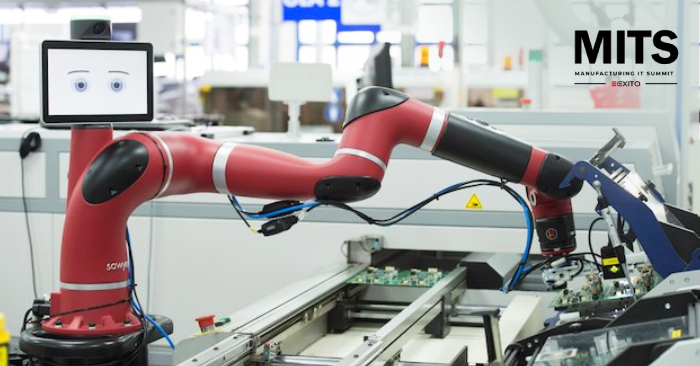

- Utilizing 3D printing in manufacturing:

As discussed previously, 3D printing technology has numerous applications in the manufacturing industry.

However, The most popular application of 3D printing is in prototype production. Utilizing both CAD and 3D printers, engineers can easily construct prototypes of new products. This ensures that the product is developed faster and with increased efficiency. Another plus point of 3D printing is that there’s minimal wastage of materials and there is no requirement for creation of molds or casts, whatsoever.

4. Enhancing the stability of Supply Chain:

Besides being a boon to the manufacturing industries, Additive process manufacturing also plays a pivotal role in delivering end products to consumers, thereby maintaining the stability of the supply chain.

The Covid-19 pandemic led to the downfall of the global supply chain, as companies were heavily dependent on traditional means of manufacturing. Healthcare industries were drastically affected due to lack of access to medical supplies. To tackle this very problem, additive manufacturing came through and produced goods quickly and in high volumes.

Conclusion:

After discussing the advantages of additive manufacturing, we can readily come to the conclusion that 3D printers are the future of manufacturing industries. 3D printers are now used to originate components ranging from medical implants to aerospace parts. and this trend is only expected to rise exponentially in the future.

As 3D printers become more advanced yet less expensive, industries can produce small batches of products without incurring huge expenses. Finally, 3D printing’s most distinct feature is scalability that ensures production of a wide range of products from the smallest components to large high-end components.

Furthermore, as additive manufacturing technologies keep evolving, the impact they have on industries will simultaneously grow. Through its agile and sophisticated functioning, additive manufacturing processes will entirely transform the way industries operate on a day-to-day basis.

If the above topic piqued an interest in you to learn more about the use of additive technologies in manufacturing industries. Then make sure to attend our exclusive 22nd edition Manufacturing IT Summit where you’ll be enlightened by industry experts about the latest tech trends that can drive your industry’s success rate!