In today’s modern and futuristic era, you would surely have heard the term, “Nanotechnology”. What is Nanotechnology? Some might say it’s a buzzword, but according to many, it’s a game changer. Its meaning is evident in the term itself, as nano means small. Nanotechnology as a whole, means the science working with materials at the nano scale is revolutionizing how we make things.

Nanotechnology involves manipulating matter at the scale of atoms and molecules, typically at dimensions smaller than 100 nano meters. This enables scientists and engineers to design and create materials with enhanced properties and functionalities.From creating super-strong nano materials to developing Advanced Technologies, its applications are endless and its benefits immense.

In this blog, we’re diving into the world of nanotechnology and how it’s reshaping manufacturing. Read along as we break down the benefits of nanotechnology, nanotechnology application and explore the wide-ranging uses of nanotechnology in different industries.

Besides that, we shall also take a quick look at how innovation is being driven through nanotechnology in medicine and nanotechnology engineering. From improving fuel efficiency to tackling medical challenges, nanotechnology is changing the game, adversely. So, let’s explore how these tiny technologies are making a huge difference in the world of manufacturing.

The role and uses of nanotechnology in manufacturing

Nanotechnology in manufacturing plays a key role in today’s era, from enhancing the material properties, increasing precision and reducing energy consumption, promotes sustainability through effective use of such technologies, and possesses properties that make manufacturing simpler than ever.

1. Enhanced Material Properties: Nanotechnology enables the creation of nano materials with unique properties such as increased strength, flexibility, conductivity, and durability. These advanced materials can be used in manufacturing to produce lighter, stronger, and more resilient products.

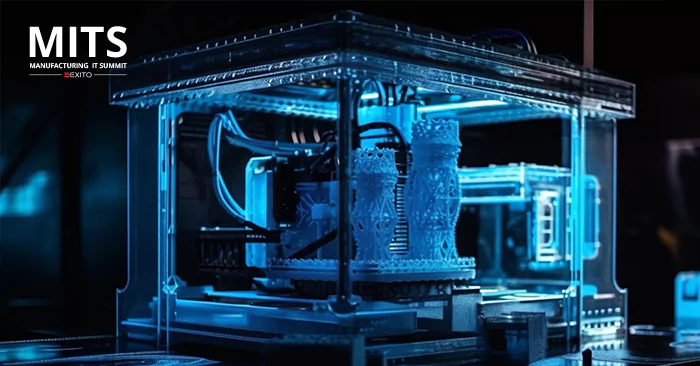

2. Miniaturization: Nanotechnology allows for the miniaturization of components and devices, leading to the development of smaller and more efficient products. This is particularly valuable in industries like electronics, where smaller components can improve performance and enable the creation of compact devices.

3. Precision Manufacturing: Nanotechnology facilitates precise control over the manufacturing process at the atomic and molecular levels. This precision allows for the fabrication of complex structures and devices with exact specifications, leading to improved quality and consistency in manufacturing.

4. Improved Energy Efficiency: Nanotechnology offers opportunities to enhance energy efficiency in manufacturing processes. For example, nano materials can be used as coatings to reduce friction and wear in machinery, leading to energy savings and extended equipment life span.

5. Environmental Sustainability: Nanotechnology can contribute to environmental sustainability in manufacturing by enabling the development of eco-friendly materials and processes. Nano materials can be engineered to be recyclable, biodegradable, or less resource-intensive, reducing environmental impact.

7. Drug Delivery and Healthcare: The benefits of nanotechnology are widely seen in the healthcare industry, especially in processes like drug delivery. It has revolutionized drug delivery systems by enabling the development of nano-sized carriers that can target specific cells or tissues in the body. This technology has the potential to improve the efficacy and safety of pharmaceuticals, leading to better healthcare outcomes.

8. Sensors and Diagnostics: Nanotechnology applications go beyond drug delivery. They are essential in the development of advanced sensors and diagnostic devices for monitoring various parameters in manufacturing processes. These nano-enabled sensors can provide real-time data on factors such as temperature, pressure, and chemical composition, enabling better process control and optimization.

9. Nano electronics: Nanotechnology engineering has truly paved the way to develop nano electronic devices with enhanced performance and functionality. These nano-sized electronic components are used in a wide range of applications, including computing, telecommunications, and sensing.

Applications of Nanotechnology in Manufacturing

Now that we’ve already provided answers to questions like “What is Nanotechnology”, and “What are the roles and benefits of Nanotechnology”, It’s time to get on to the next step of discussing nanotechnology applications in reshaping the manufacturing landscape across diverse industries, offering a plethora of benefits of nanotechnology ranging from enhanced product performance to cost savings. Let’s explore some simplified examples of how nanotechnology is making a big impact:

i). Advancing Electronics:

In the semiconductor industry, nanotechnology is driving significant progress, especially with nano materials being a huge contributor to this progress. Consider transistors, the fundamental building blocks of electronic devices. With nano scale innovations like carbon nano tubes (CNTs) and graphene chips, transistors have become incredibly small and efficient. This means faster and more powerful computers, smartphones, and other gadgets, producing a well-functioning byproduct of nanotechnology engineering.

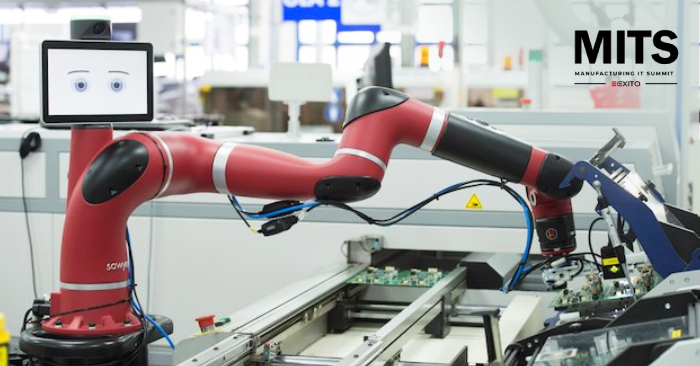

ii). Harnessing Minute Machines:

Researchers are engineering nano machines from tiny molecules, creating nano motors and nano robots with remarkable capabilities. Another commendable function of nano machines is in the vast field of medicine. Nanotechnology in medicine is in fact bringing hope to the healthcare industry as these nano machines can be programmed to perform precise tasks, such as delivering drugs to specific locations within the body. This opens up exciting possibilities for targeted and personalized medicine, offering hope for more effective treatments for diseases like cancer.

iii). Improving Materials for Fuel Efficiency:

Nanotechnology is also revolutionizing materials used in manufacturing processes, such as polymers for adhesives, sealants, and coatings. By dispersing nano particles into these materials, they gain remarkable properties like enhanced strength, chemical resistance, and even fire resistance. This not only improves the performance and durability of products but also contributes to environmental sustainability by reducing the need for frequent replacements. Hence, technologies like these have proved to positively impact the environment while performing its duties with utmost efficiency.

iv). Tackling Friction with Precision:

In the quest for efficiency, nanotechnology is addressing challenges like friction in manufacturing processes. By incorporating nano particles into lubricants, they act as miniature ball bearings, rolling between surfaces to reduce heat, wear, and the risk of oil failure. This breakthrough promises longer-lasting machinery and reduced energy consumption, leading to cost savings and environmental benefits. while nanotechnology deals with incredibly small dimensions (measured in nano meters), its impact on manufacturing is monumental. By harnessing the power of the nano scale, we’re unlocking a world of possibilities for innovation, efficiency, and sustainability in manufacturing processes and product development.

These applications illustrate the myriad uses of nanotechnology in enhancing lubrication, extending machinery life span, and optimizing energy utilization.

In conclusion

Through this blog, we have successfully proved that the promise of nanotechnology is a tangible force propelling us towards a future where the tiniest advancements yield monumental results. So, as we navigate this intricate world of nano-innovation, let’s embrace the magnitude of possibilities it holds, for within the minuscule lies the power to transform our Manufacturing Landscape and shape a brighter tomorrow.