The manufacturing sector’s technological developments are critical to the global economy’s progress. Manufacturing innovations that improve the productivity and long-term viability of entire production processes are the newest manufacturing trends. On the other hand, manufacturing companies are looking to retain productivity with a smaller workforce in the aftermath of the COVID-19 outbreak. As a result, startups are working on smart sensors, immersive technological devices, and wearables that eliminate the need for workers to be physically present.

Industry 4.0 technologies are changing how the manufacturing industry works, making them more agile and resilient than ever before. While it’s easy to get caught up in the whirlwind of change, it’s also important to step back and consider the big picture. In 2022, the manufacturing industry is projected to see specific changes that, if properly utilized, can stimulate innovation and help organizations stay competitive. This blog will cover several key areas for manufacturers to focus on, in-order to shape 2022 and beyond.

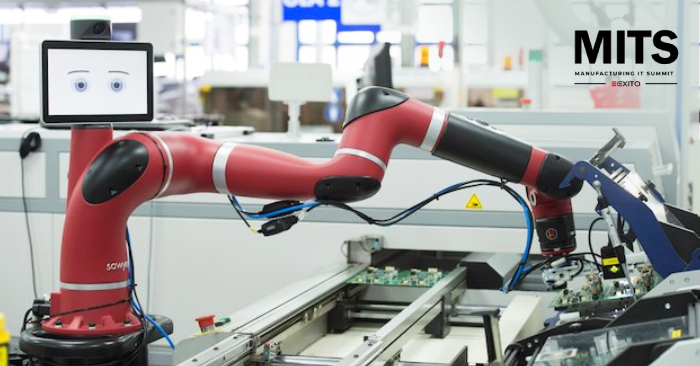

Industrial automation

Although automation is not new, it has become more accessible, simple, and cost-effective since the development of robotic technology. It has also reduced and eliminated possible risks to human life, making the manufacturing process safer. Intelligent automation is a critical technology that will change the manufacturing industry because it simplifies numerous material handling, assembly, and painting processes.

According to the Industrial Automation Report 2021-2028, the global industrial automation market is expected to grow at a CAGR of 9.2%, from USD 191.74 billion in 2021 to USD 355.44 billion in 2028.

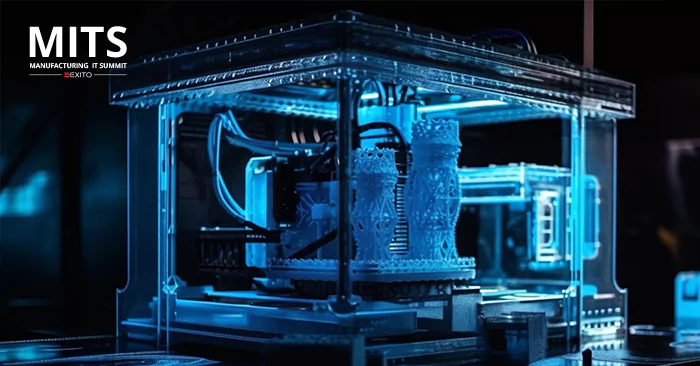

Additive manufacturing (3D printing)

Manufacturing will be transformed in the future years by additive manufacturing. Design freedom, higher-performing goods, enhanced plant productivity, sustainable procedures, and a shorter time to market are all advantages that come at little or no extra cost.

Aerospace and defence are at the forefront of additive manufacturing, closely followed by automotive production.

Xact Metal is a 3D metal printing startup based in the United States. The printers’ high-speed digital galvanometer system allows faster metal additive manufacturing printing. The solution 3D prints components in various metals and comes with software that makes machine setup, control, and monitoring a breeze.

Machine Learning and Artificial Intelligence

Artificial intelligence (AI) is intelligence that can mimic human cognitive abilities. On the other hand, machine learning (ML) refers to computer learning or improving performance by analysing and understanding data. Machine learning technologies are utilized in real-time in AI to allow factory machines to fulfill their tasks. Simultaneously, machine learning can be used in data science to evaluate the obtained data to uncover patterns and create future predictions, enabling you to build a smart manufacturing industry.

AI aids in the improvement of product quality and leads to market adoption. While AI, machine learning, and data science may sound similar, each has a distinct role and effect in the market.

Zeominds is a new AI-based product and service provider established in India. The software analyses machine data from IoT sensors in real-time. It detects signs of failure and deterioration in performance, lowering maintenance costs and enhancing machine productivity in industries.

Supply Chain Nearshoring

In 2020 and 2021, the global supply chain faced considerable challenges. The manufacturing industry will continue to face problems due to supply chain challenges. To address various supply chain difficulties, manufacturers frequently turn to local vendors.

While this may raise product prices, it can also be viewed as an opportunity to improve agility, flexibility, and quality, all of which lead to higher customer satisfaction. As a result of the globalization to localization strategy, on-shoring is expected to continue in 2022. This tendency will hasten the adoption of distributed or local manufacturing, a customer-centric strategy for meeting rising customer demands.

Learn more at Manufacturing IT Summit

Event Organised by Exito Media Concepts