Industry 4.0, a new industrial revolution, is set to change the world of manufacturing as we know it. It is an initiative of the German government and has been gaining momentum in India as well.

The Indian manufacturing sector hasn’t had much of an opportunity to use Industry 4.0 technologies due to the absence of technology that would enable this transformation – until now!

The manufacturing sector in India is projected to grow by 10% annually, which will increase its share of GDP from 16% in 2017 to 25% by 2030. This growth will be driven by Industry 4.0 technologies, which are being adopted at an unprecedented pace in India.

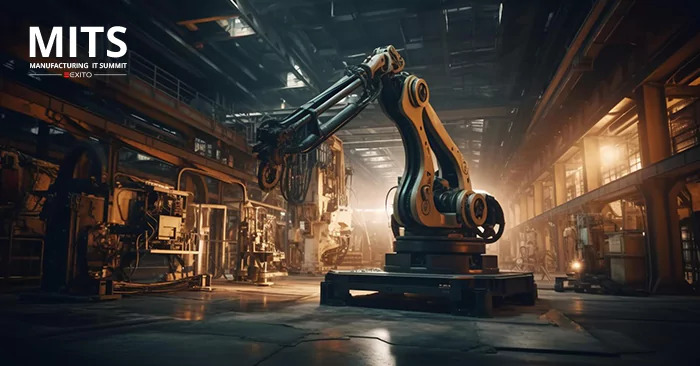

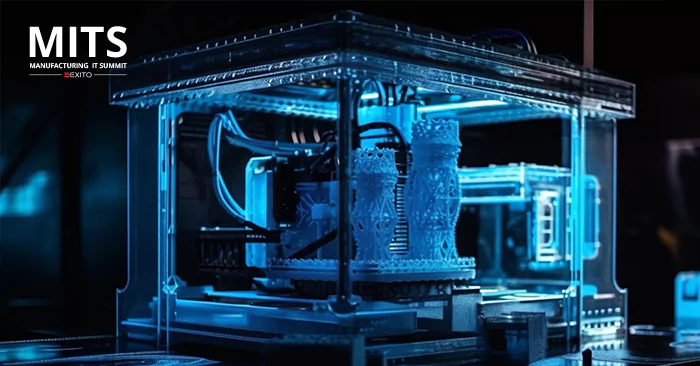

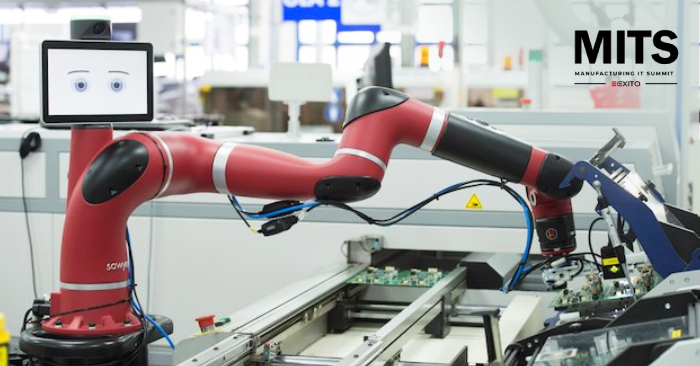

The digital supply chain has evolved and enabled companies in India to make the best use of Industry 4.0 with technology such as IoT devices, cloud platforms, AI assistants, 3D printing, and robotics.

With Industry 4.0 technologies, industries can be more efficient and productive than ever before. They can connect their machines with other machines and share data to get real-time feedback on how the production process is going on.

Digitization of Manufacturing

COVID-19 has demonstrated the importance of moving to digitally-enabled smart manufacturing and flexible supply chain models. Diverse sourcing and digitalization will be critical to guaranteeing long-term recovery and developing more robust, creative supply chains.

Given the present pandemic scenario, India may benefit from the fact that companies all over the world are seeking a new source of supplies. AI, data analytics, and IoT can all assist in improving and speeding up the process in this area. Manufacturers can now manage quality control and automated production processes while also keeping track of the newest trends in order to reinvent manufacturing methods in response to client demand using real-time data.

Manufacturers may also use this technology to guarantee that safety and environmental regulations are fulfilled, which will improve employee health and morale. As a result, firms may simultaneously scale up production, simplify processes, and increase productivity to fulfill client expectations.

Initiatives by the government

Industry 4.0 is also being propelled by government efforts and investments to promote the notion of smart manufacturing. In India, the government established SAMARTH-Udyog Bharat 4.0 to help firms understand Industry 4.0 and actively push the construction of a smart industrial environment. According to the Indian government, just around 10% of manufacturers now have an Industry 4.0 strategy.

Industry 4.0, in which everything is connected, and every data point is examined, is certainly going forward in India’s industrial industry. In fields like medicines and textiles, Indian enterprises are at the forefront of R&D and have already established themselves as worldwide leaders. Automation and robots are also getting the attention they deserve from the industry.

Conclusion

Industry 4.0 has already changed the way we work in factories by increasing efficiency and improving product quality while also providing better customer service to our customers.

With India being one of the most potential markets globally, we must find a way to revive the sector. Industry 4.0 technologies such as IoT and AI prove to be game-changers. With these new technologies, Indian manufacturers will be able to increase their competitiveness and efficiency while improving workers’ job quality and skills.

Industry 4.0 is the fourth industrial revolution, and it is proving to be a game-changer for the Indian manufacturing sector. It has enabled manufacturers to automate their production processes, which has helped them to increase their efficiency and productivity.