Predictive analytics is a powerful tool to help manufacturing companies make better decisions and improve efficiency. It provides a competitive edge for organizations in the Manufacturing Industry. It can help manufacturers identify new trends and opportunities and address challenges with an efficient solution.

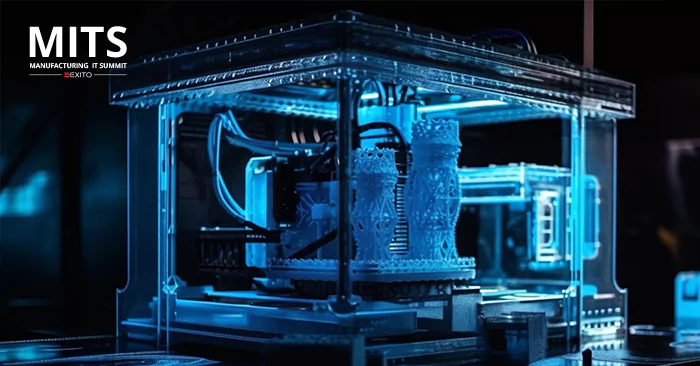

Predictive analytics can forecast demand, manage inventory, and predict maintenance needs to minimize downtime. It is also used for quality control by identifying defective products before shipping. It is an excellent example of how data science can be applied to business problems to increase decision-making effectiveness.

Predictive analytics uses statistical techniques to identify patterns in data and use this information to make predictions. It is a powerful tool that can help manufacturing companies predict demand and make better production decisions. Accordingly, IDC estimates that spending on AI-powered applications, such as predictive analytics, will increase from $40.1 billion in 2019 to $95.5 billion by 2022.

Some advantages of predictive analytics

1.Predict performance by detecting patterns

Predictive analytics can filter through massive volumes of historical data far faster and more precisely than humans. We can enhance output by 10% without losing first-pass yield by using machine learning technology to recognize recurrent patterns and other connection factors.

AI and machine learning can look for trends and combine them to assist your company in uncovering possible efficiency gains, foresee problems, and cut costs.

2.Analyze market trends

Another application for PA is forecasting customer demand. Knowing what to expect in the future might help you determine what to do next.

Every business conducts some manual market research. For example, some consumer items are seasonal and sell better at certain times of the year. Demand forecasting may be aided by predictive analytics using statistical algorithms, which isn’t a new concept.

Customers’ future purchase patterns, supplier connections, market availability, and the impact of the global economy are all influenced by a variety of variables. The only way ahead is to manage them all through PA.

3.Assists with inventory management

Supply chain management—stocking raw supplies, keeping completed goods, and coordinating transportation and distribution networks—is a complex commercial process that necessitates significant training, data from several sources, and excellent decision-making ability.

A computer model based on your data, on the other hand, may help supply chain managers make more confident and precise judgments. For example, such a model may ensure that you are never overstocked, understocked, or overburdened with unsaleable goods, even determining the best positioning of things on your shelves.

4.Enhance the product’s quality

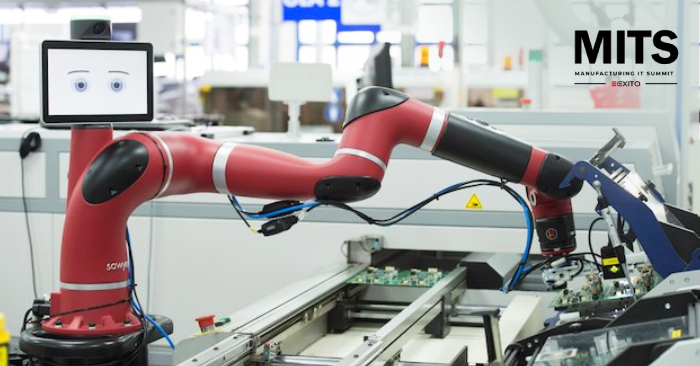

There are make-or-break steps in every manufacturing process where overall product quality is determined; these are frequently handled by humans who are prone to error. Artificial intelligence (AI) and machine learning are cutting-edge alternatives to this problem. Sensitive manufacturing stages can be delegated to robots that use machine learning to improve with each use. When compared to human-made items, this results in higher product quality.

PepsiCo, for example, has used machine learning systems to improve how it makes one of its famous Lays chips, from estimating potato weight to examining the texture of each chip with a laser system. These have resulted in a 35% increase in product quality.

Conclusion

Predictive analytics is undoubtedly a key boon for manufacturers as it can help them identify new trends and opportunities and address challenges with an efficient solution. It can also help manufacturers understand their customers better and create products that will be successful in the market.