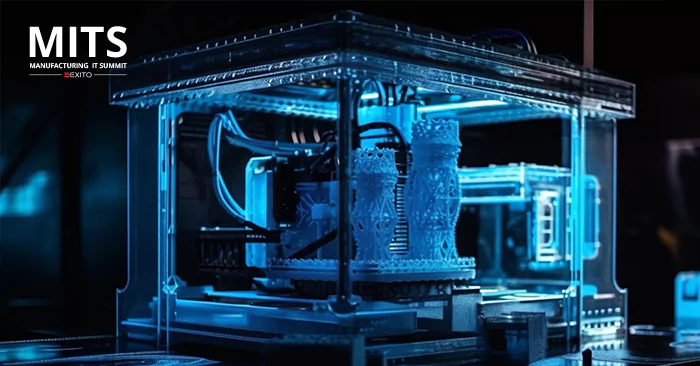

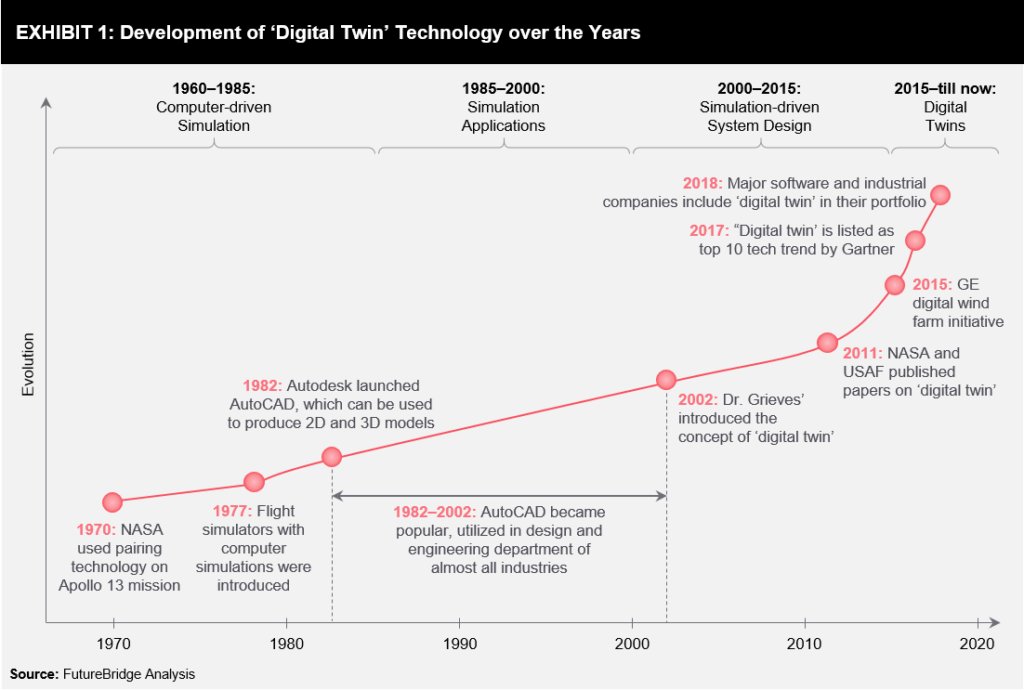

Digital Twin to the rescue, for complex IoT systems. .The idea of digital twin technology in IoT has been in talk for more than decades now,but many companies are yet to adopt the same. As per Gartner 2019 research, 13% of companies with IoT projects are already using digital twin, while 62% of the other companies are in the process of bringing in the use of digital twin for their IoT projects. Around 1970, NASA was amongst the early adopters of digital twin.

Twin-win for Manufacturing Industry. .

Digital twin technology for IoT is one of the fastest-growing among the top manufacturing technology trends of 2021. Most of the twin applications are spread across manufacturing,

which includes –

●Product Development – With the help of digital twin, engineers can test various aspects of a product before actually launching it. Engineers then plan the feasible strategy as per the output it generates.

●Product re-creation – In order to create a different product version, a digital twin can be used to provide similar product’s data to the production system for re-creation. This will significantly reduce the overall production time required.

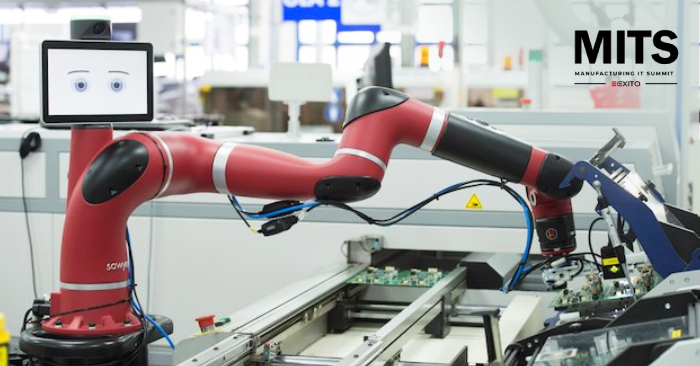

●Predictive Maintenance – Companies can predict possible downtime of machines by deploying digital twins. This escalates the manual effort and handles failure much before it actually takes place.

●Aerospace – Engineers perform predictive analysis with the help of digital twin to detect any sort of future issues with respect to engines, airframes and other aero parts. This ensures life safety to a greater extent.

●Business performance Improvement – Digital twin can be employed to analyze and monitor defects in products and dynamically recommend engineers on the same. The list is way beyond the above mentioned and includes applications such as self- driving car design and development, process planning, system virtual setup etc. With a range of powerful applications and possibilities, it is doubly exciting to have a look at

some amazing use cases in production –

●Kaeser – Kaeser is among the top manufacturing U.S. organizations, who applied digital twins and transitioned itself from mere product sellers to selling a service. The applied Digital Twin Technology in IoT system constantly monitors and provides the company with component’s operational data during its process lifecycle. Outcome of

which was, the company saw significant business growth and reduced commodity costs by nearly 30%. The company also managed to welcome 50% of all major sellers using digital twins.

●Stara – Stara, a Brazil based tractor manufacturing industry utilized digital twin technology in IoT for modernizing farming ways. Industries can enhance its equipment performance, by fitting its tractors with IoT sensors. Also, using Stara’s methods, farmers reduced 21% of seed usage and 19% of fertilizer usage, leading to significant cost saving.

●Amazon – Amazon utilized digital twins in e-commerce by flashing consistent remarketing ads. As a result, the company is gaining huge traction and business growth.

●Addepto – Using digital twins, Addepto developed an operation control system to collect aerospace information. This way the industry improved decision-making and saved a great deal of money, time and reduced defects downstream.

“The rise of digital twins coincides with the rise of the IoT. When buying machines and other assets, support for digital twins and continuous development of twin capabilities should be a selection factor,” says Schulte, Distinguished Vice President Analyst, Gartner.

Learn more about this at the Manufacturing IT Summit

Event organized by Exito Media Concepts